Volare Mouthpieces are not only made based on the ideas of players’ alone. They are developed with teamwork by Japanese special craftsmen. Every player must experience for themselves just how different these mouthpieces are. A newly born new standard “Volare-Type” has just arrived in the universe!

This project was founded in Japan by legendary tuba virtuoso Roger Bobo.

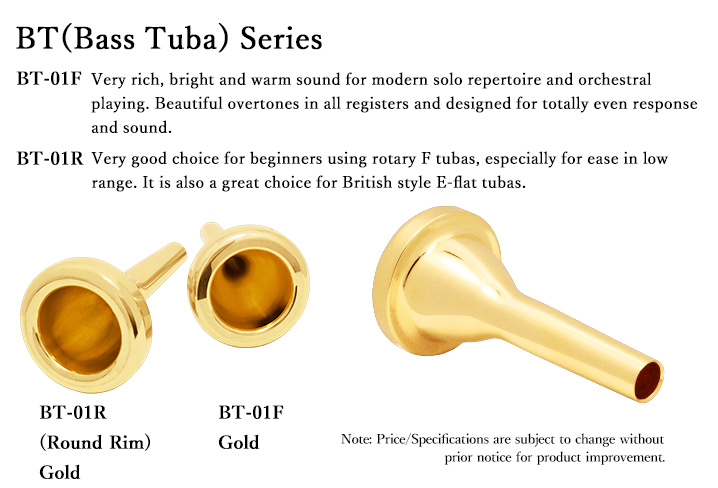

All concepts and ideas are based on his innovation. What we are most excited about is the very first Volare Mouthpiece, BT-01F, idea by the Maestro himself. The craftsmen behind this work are not the typical instrument makers. They produce many other items by hand using the traditional spirit of Japanese craftsmen. Maestro Bobo has also collaborated with many of the world’s top professional tubists and greatly values their influence and feedback.

Now, Volare is not only for the tuba products. We also have developed and are making products for other low brass instruments! When Maestro tried one of our first mouthpiece designs, he shouted, “Volare!” Volare is an Italian word which means “To Take Flight!”

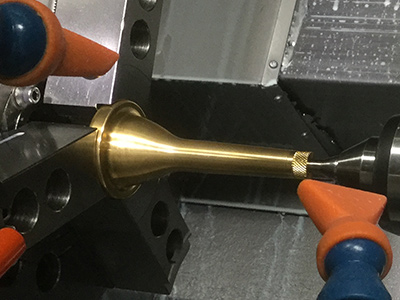

Japan still has many special craftsmen who emphasize fine details and working by hand.

This work ethic is based on intuition combined with years of experience. Our mouthpieces are made by such craftsmen in conjunction with Maestro and other professional players’ ideas.

Maestro’s request was very simple and encompassed three categories. These are: Great Resonance, Evenness of Sound and a Rich Tone in all registers. In line with this concept, we never compromise and put immense effort into each mouthpiece we make. We respect and often improve upon several types of mouthpieces from past makers (eg. Helleberg-Type, Geib-Type, etc.) and also research the differences between U-Cup and V-Cup. Our mouthpieces are produced and sold while maintaining thorough quality with each product,and this brings all players joy, inspiration and helps them achieve the expression they desire. Now, the newly-born new standard “Volare-Type” has officially arrived in the universe!

Greetings from Roger Bobo and six points of Volare development.

final confirmation of the "Neo"Volare Project

The shape of each mouthpiece is designed with extreme precision using Industrial Technology Center Okayama’s 3D Micro Measuring Machine (ZEISS). This has been an enormous success for our development. Such Technology ensures absolute consistency when designing the contour of each model.

We thoroughly researched the finest material of multiple kinds of brass at Okayama University Laboratory. We have sought to solve issues regarding intonation flaws using only the highest quality of brass available. We then chose the best acoustic balance and decided upon the weight of our mouthpieces. Volare has also avoided the use of hammering the model number and company seal onto our products. We have tried to avoid any metal-fatigue due to hammering and have adopted the use of laser-printing. This process has proved to be a great success.

We researched the effects of stress and endurance regarding embouchure in all registers and dynamics. Then we designed a special type of cutting called, “Triple−Edged Flat Construction,” for the ideal inner-rim shape. You will find this to be very comfortable to the embouchure while also reducing fatigue.

Volare mouthpieces are designed by a Micro Measuring Machine (ZEISS), but our craftsmen also understand the invaluable role of human-touch in the pursuit of excellence. Numerical values used in programming were replaced with human senses then the human senses were converted back to numerical values and applied to the machine. The cup, throat, bore and back bore cuttings are the most important part for producing the best sound and creating this is an arduous process when problems often seem invisible. But using the fine skill of our craftsmen, we can cut in precisely the right place according to their expertise and knowledge. We have often received feedback such as, “I have tried two mouthpieces which are the same model, but the sound is somehow different.” We have addressed such concerns according to the method above.

We also conducted wind-tunnel experiments at Shimane University Laboratory. As a result of these tests, we arrived at the best ratio in size between cup and shank. Much to our surprise, the outer design played a critical role in the results of the wind-tunnel experiment. Ultimately, these trials were a great success in aiding the development of airflow in every register and all dynamics.

The realization of quality which allows each artist to perform with ease and consistency is exactly what motivates and inspires the team at Volare. Volare is a crystallization of Japanese craftsmanship and ingenuity. Our products are made with the pride and spirit of Japan.

This new Volare model differs slightly from our first production.

At the adamant request of the Maestro, in order to maintain the prototype according to its design and to minimize polishing, we are manufacturing by two processes before applying gold plating.

This also increases plating strength. As a result, there may be hairlines or uneven plating, but it is necessary to keep the original shape of the prototype.

This will cause no hindrance to performance.

Specifics

| Cup Diameter | Rim Width | Throat/Bore Size |

| 32.03mm Shallow Shape | 8.35mm | 7.50mm |

BT-01F Gold

market price

Silver

price38,000JPY

Specifics

| Cup Diameter | Rim Width | Throat/Bore Size |

| 32.03mm Shallow Shape | 8.35mm | 7.50mm |

BT-01R(Round Rim)Gold

market price

Silver

price38,000JPY

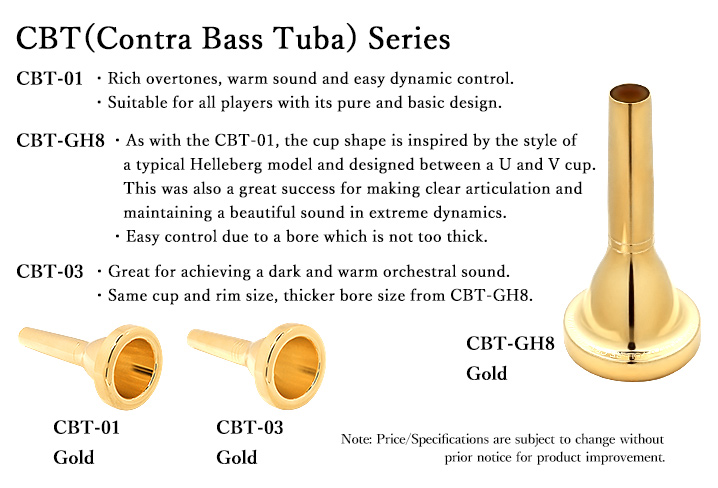

Specifics

| Cup Diameter | Rim Width | Throat/Bore Size |

| 32.39mm Medium Deep Shape | 7.06mm | 8.30mm |

CBT-01 Gold

market price

Silver

price38,000JPY

Specifics

| Cup Diameter | Rim Width | Throat/Bore Size |

| 33.08mm Medium Deep Shape | 7.20mm | 8.10mm |

CBT-GH8 Gold

market price

Silver

price38,000JPY

Specifics

| Cup Diameter | Rim Width | Throat/Bore Size |

| 33.50mm Medium Deep Shape | 7.00mm | 8.30mm |

CBT-03 Gold

market price

Silver

price38,000JPY

copyright 2016-2020 bass-clef.co.jp